Simmonds

Simmonds is the inventor of the nylon locking nut. Although many applications have moved to cheap Chinese made locking nuts, we see customers coming back because of issues they have with the Chinese parts.

MHT PH 105 CN CF PH 135 12 point nut DHE series SNLA 069 Nut

1. NYLSTOP

- Superiority against vibration compared to alternatives.

- reusability = 15 cycles

- automation because of Q + very low scatter à low cost ß

- no non-conforming nuts, no inspection needed

- Strong chemical resistance of the nylon

- Superior material Q à HV

- Corrosion siligard protection 600h

- 100 °C with peak up to 140°C

NYLSTOP LOCKING

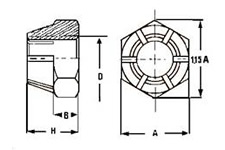

The self-locking effect of a NYLSTOP nut is obtained by a cylindrical non-threaded nylon ring, which is crimped in a housing situated on the upper part of the nut.

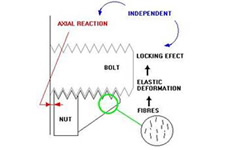

THE LOCKING PRINCIPLE

Before penetration of the bolt into locking feature of the NYLSTOP nut, it functions as a standard nut.

As the outer diameter of the bolt is bigger than the internal diameter of the locking feature, resistance will occur as soon as the bolt is penetrates the locking feature. This resistance increases the further the bolt penetrates the nut. The result is a significant axial pressure that compensates completely for the differences in tolerances between, the flanks of, as well as the bolt and nut threads. This “metallic” locking position is reinforced by the radial action of the nylon ring engendered by compression during assembly.

The mechanical continuity realised between the bolt and the NYLSTOP nut will be maintained in all circumstances even in the most severe working conditions.

ADVANTAGES OF THE NYLSTOP NUT

1. Excellent resistance to vibrations.

Most of the unintentional loosening of nuts is due to vibration, repeated shocks or distortion. The efficacy of a self-locking nut can only be precisely determined after comparative testing. All currently completed tests, in our own laboratories and official test laboratories, indicate the superiority of Fairchild NYLSTOP nuts compared to similar alternatives. This superior performance is maintained by rigid process control systems throughout the complete production process.

2. Great possibilities of reusability

It is important and advantageous that a self-locking nut can be reused several times.

One of the biggest advantages of the NYLSTOP locking nut is the flexibility of the locking feature. Therefore, The NYLSTOP locking nut excels in that respect offering a minimum of 15 cycles without prejudicing locking performance and resistance to vibration.

3. Cost effective

The NYLSTOP nut not only offers technical and performance advantages, it also reduces assembly costs. The high quality of the NYLSTOP nuts permits a complete automation of installation because of constant quality and very low scatter of the locking torque ranges. This permits installation without concerns of defective or non-conforming nuts and reduces the cost of monitoring and tight inspection.

4. Chemical resistance

The Nylon polyamide used in the NYLSTOP nut is completely insensitive to carbon tetrachloride, carbon bisulphide, concentrated alkalis, hydrocarbons (petrol, kerosene, gasoline, etc…), solvents (trichloroethylene, perchlorethylene, ketones etc…), alcohols, aldehydes, soaps and detergents, motor oils & diluted acids.

The Nylon also resists most organic acids with the exceptions of for formic acid and phonic acid. The Nylon is attacked by mineral acids and strong bases (nickel baths, acid solutions based on chrome or sulphur)

5. Temperature resistance

The NYLSTOP nut has a safe operating temperature range between -40°C and 100°C, it can also support point temperatures up to 140° C for a brief period of time (i.e. passing through a steriliser)

6. Corrosion resistance

The NYLSTOP nut has excellent corrosion resistance. The standard product in Class 8 yellow zinc plated achieves a salt spray test resistance of min. 200 hours. With the special SILIGARD treatment, we guarantee up to 400 hours salt spray test.

7. Material quality

NYLSTOP nuts are different from our competitors because of the guarantee they give in used materials and material strengths.

According to the standards, a class 8 nut requires a minimum hardness of 233HV for all diameters between 18 and 39 mm, and a minimum hardness of 207HV for diameters between 42 and 100 mm to achieve the specified strength of 920 Mpa. Normally hardening is required but the specified strength of 920 Mpa is achieved by the NYLSTOP nut without hardening.

Fairchild NYLOC class 8 nuts are not treated (hardness188HV min. – 302HV max.) and guaranteed 920Mpa, so eliminating the extra cost of hardening.

If hardening of the nut is mandatory, than we would prescribe the use of a class 10 nut.

8. Special quality approvals

NYLSTOP meets the high railways standards, and is approved as a high quality nut.

9. Traceability

All NYLSTOP nuts have a complete traceability.

- Lot numbers are standard on all orders and labels

- Marking of steel class is available on all nuts.

| class 10 steel | Stainless steel | class 8 steel | Nominal Diam. | Pitch | Ref (recplace ** with material code) | A h 13 | B min. | H max. | T min. | Weight in kg 100 pcs (steel) |

|---|---|---|---|---|---|---|---|---|---|---|

| • | 2,5 | 0,45 | M2,5 P ** | 5 | 1,7 | 4,3 | 2,0 | 0,038 | ||

| • | • | 3 | 0,50 | M3 P** | 5,5 | 1,7 | 4,9 | 2,1 | 0,050 | |

| • | • | 4 | 0,70 | M4 P ** | 7 | 2,3 | 6,0 | 2,9 | 0,080 | |

| • | • | 5 | 0,80 | M5P ** | 8 | 3,5 | 6,8 | 4,4 | 0,150 | |

| • | • | • | 6 | 1,00 | M6 P ** | 10 | 3,9 | 8,0 | 4,9 | 0,300 |

| • | • | 7 | 1,00 | M7 P** | 11 | 4,9 | 9,1 | 6,1 | 0,375 | |

| • | • | • | 8 | 1,25 | M8P** | 13 | 5,1 | 10,6 | 6,4 | 0,640 |

| • | • | 8 | 1,00 | M8x100P ** | 13 | 5,1 | 10,6 | 6,4 | 0,640 | |

| • | • | • | 10 | 1,50 | M10P ** | 16 | 6,4 | 12,6 | 8,0 | 1,150 |

| • | • | 10 | 1,25 | M10x125P ** | 16 | 6,4 | 12,6 | 8,0 | 1,150 | |

| • | • | 10 | 1,00 | M 10x100 P ** | 16 | 6,4 | 12,6 | 8,0 | 1,150 | |

| • | • | • | 12 | 1,75 | M12P ** | 18 | 8,3 | 15,0 | 10,4 | 1,700 |

| • | 12 | 1,50 | M12x150'P ** | 18 | 8,3 | 15,0 | 10,4 | 1,700 | ||

| • | • | 12 | 1,25 | M 12x1 25 P ** | 18 | 8,3 | 15,0 | 10,4 | 1,700 | |

| • | • | • | 14 | 2,00 | M14P ** | 21 | 9,7 | 17,5 | 12,1 | 2,650 |

| • | • | • | 14 | 1,50 | M14x150P ** | 21 | 9,7 | 17,5 | 12,1 | 2,650 |

| • | • | • | 16 | 2,00 | M16P ** | 24 | 11,3 | 20,1 | 14,1 | 4,050 |

| • | • | 16 | 1,50 | M16x150P ** | 24 | 11,3 | 20,1 | 14,1 | 4,050 | |

| • | • | • | 18 | 2,50 | M18P ** | 27 | 12,1 | 22,3 | 15,1 | 5,300 |

| • | • | 18 | 1,50 | M18x150P ** | 27 | 12,1 | 22,3 | 15,1 | 5,300 | |

| • | • | • | 20 | 2,50 | M20 P ** | 30 | 13,5 | 23,5 | 16,9 | 7,400 |

| • | • | 20 | 1,50 | M20x150P ** | 30 | 13,5 | 23,5 | 16,9 | 7,400 | |

| • | • | • | 22 | 2,50 | M22 P ** | 32 | 14,5 | 26,0 | 18,1 | 8,350 |

| • | 22 | 1,50 | M22x150P ** | 32 | 14,5 | 26,0 | 18,1 | 8,350 | ||

| • | • | • | 24 | 3,00 | M24 P ** | 36 | 16,2 | 28,2 | 20,2 | 12,600 |

| • | 24 | 2,00 | M24 x 200 P** | 36 | 16,2 | 28,2 | 20,2 | 12,600 | ||

| • | 27 | 3,00 | M27 P ** | 41 | 18,0 | 32,5 | 22,5 | 18,500 | ||

| • | 27 | 2,00 | M27x200 P** | 41 | 18,0 | 32,5 | 22,5 | 18,500 | ||

| • | 30 | 3,50 | M30 P ** | 46 | 19,4 | 35,0 | 24,3 | 26,000 | ||

| • | 30 | 2,00 | M30 x 200 P ** | 46 | 19,4 | 35,0 | 24,3 | 26,000 | ||

| • | 33 | 3,50 | M33 P ** | 50 | 21,9 | 38,4 | 27,4 | 35,000 | ||

| • | 36 | 4,00 | M36 P ** | 55 | 23,5 | 41,5 | 29,4 | 44,000 | ||

| • | 39 | 4,00 | M39 P** | 60 | 25,4 | 44,7 | 31,8 | 58,000 | ||

| • | 42 | 4,50 | M42 P** | 65 | 25,9 | 47,5 | 32,4 | 69,000 | ||

| • | 45 | 4,50 | M45 P** | 70 | 27,5 | 51,5 | 34,4 | 90,000 | ||

| • | 48 | 5,00 | M48 P ** | 75 | 29,1 | 55,0 | 36,4 | 115,000 | ||

| • | 52 | 5,00 | M52 P ** | 80 | 32,3 | 59,2 | 40,4 | 130,000 |

The nuts indicated with a black dot are standard manufactured

NYLSTOP LOW VERSION

| class 10 steel | Stainless steel | class 8 steel | Nominal Diam. | Pitch | Ref (recplace ** with material code) | A h 13 | B min. | H max. | T min. | Weight in kg 100 pcs (steel) |

|---|---|---|---|---|---|---|---|---|---|---|

| • | • | 4 | 0,70 | M4T ** | 7 | 1,8 | 4,7 | 2,3 | 0,080 | |

| • | • | 5 | 0,80 | M5T ** | 8 | 2,6 | 5,6 | 3,2 | 0,130 | |

| • | • | • | 6 | 1,00 | M6T ** | 10 | 2,4 | 6,1 | 3,0 | 0,210 |

| • | 7 | 1,00 | M7T ** | 11 | 2,5 | 6,5 | 3,0 | 0,265 | ||

| • | • | • | 8 | 1,25 | M8T ** | 13 | 3,7 | 8,8 | 4,6 | 0,480 |

| • | 8 | 1,00 | M8x100T ** | 13 | 3,7 | 8,8 | 4,6 | 0,480 | ||

| • | • | • | 10 | 1,50 | M10T ** | 16 | 5,2 | 11,1 | 6,5 | 0,930 |

| • | • | 10 | 1,25 | M10x125T ** | 16 | 5,2 | 11,1 | 6,5 | 0,930 | |

| • | 10 | 1,00 | M10x100T ** | 16 | 5,2 | 11,1 | 6,5 | 0,930 | ||

| • | • | • | 12 | 1,75 | M12T ** | 18 | 5,7 | 11,7 | 7,1 | 1,200 |

| • | • | 12 | 1,50 | M12x150T ** | 18 | 5,7 | 11,7 | 7,1 | 1,200 | |

| • | • | 12 | 1,25 | M12x125T ** | 18 | 5,7 | 11,7 | 7,1 | 1,200 | |

| • | • | 14 | 2,00 | M14 ** | 21 | 6,2 | 13,1 | 7,7 | 1,900 | |

| • | • | 14 | 1,50 | M14x150T ** | 21 | 6,2 | 13,1 | 7,7 | 1,900 | |

| • | • | 16 | 2,00 | M16T ** | 24 | 6,4 | 14,0 | 8,0 | 2,600 | |

| • | • | 16 | 1,50 | M16x150 T ** | 24 | 6,4 | 14,0 | 8,0 | 2,600 | |

| • | • | 18 | 2,50 | M18T ** | 27 | 7,2 | 15,5 | 9,0 | 3,320 | |

| • | • | 18 | 1,50 | M18x150T ** | 27 | 7,2 | 15,5 | 9,0 | 3,320 | |

| • | • | 20 | 2,50 | M20T ** | 30 | 8,0 | 16,6 | 10,0 | 4,600 | |

| • | • | 20 | 1,50 | M20x150T ** | 30 | 8,0 | 16,6 | 10,0 | 4,600 | |

| • | • | 22 | 2,50 | M22T ** | 34 | 8,8 | 17,6 | 11,0 | 5,400 | |

| • | • | 24 | 3,00 | M24T ** | 36 | 9,6 | 20,0 | 12,0 | 7,600 | |

| • | • | 27 | 3,00 | M27T ** | 41 | 10,8 | 22,2 | 13,5 | 10,600 | |

| • | • | 30 | 3,50 | M30T ** | 46 | 12,0 | 25,7 | 15,0 | 17,600 | |

| • | • | 33 | 3,50 | M33T ** | 50 | 13,2 | 26,2 | 16,5 | 19,600 |

The nuts indicated with a black dot are standard manufactured

2. MHT

- very high resistance against vibration

- high temperatures 280 °C (Inox: 650°C)

- reusability

- approved AQF 2 railway nut

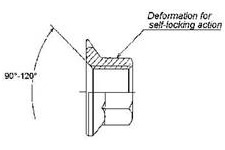

The MHT nut is presented like a standard nut prolonged with a conical part that acts as the locking feature of the nut. This conical section is tapped the same way as the hexagonal part of the nut and by compression, facilitated by six slots; a well-controlled, progressive reduction of the tapped diameter is achieved. Each of the six individual sectors of the conical part provide a beam of equal resistance, embedded at one extremity, from which the elastic deformation will assure the locking effect

The disposition of this locking feature, interdependent with the hexagonal part of the nut, permits an orientation of the material’s fibres towards the point of application of the load and confers to the assembly optimal resistance to flexion and metal fatigue.

During assembly, the bolt penetrates freely into the hexagonal part of the nut, where the thread form and shape is according to the usual standards. As soon as the bolt reaches the conical part resistance increases, provoking an elastic reaction in each of the six sectors where the nut threads are strongly pushed against the threads of the bolt. This results in an elastic tightening, that is uniformly distributed over the complete length of the locking feature, which will inhibit unintentional loosening of the nut. This is even true when the nut is still in a non-tensioned position, the locking effect of the MHT nut being independent from the axial reaction on the mounting surface while tightening it.

As the MHT nut is completely metallic the locking effect is unaffected by high temperatures and is capable of multiple reassembly without deterioration of the locking facility. Its use is particularly suitable for security assemblies subject to high working temperatures and heavy vibration.

MHT nuts apply to very high quality standards, and are approved for the railway industry with the AQF 2 certificate (Assurance qualité ferroviaire)

| Nominal diameter | Pitch | REFERENCE | A h 13 | B h 14 | H h 14 | Weight in kg 100 pcs |

|---|---|---|---|---|---|---|

| 5 | 0.80 | MHT 80/105 | 8 | 3,1 | 6,5 | 0.128 |

| 6 | 1 | MHT 80/106 | 10 | 4,4 | 8,4 | 0,273 |

| 8 | 1,25 | MHT 80/108 | 13 | 4,6 | 9,2 | 0,471 |

| 10 | 1,5 | MHT 80/110 | 17 | 5,9 | 12 | 1,063 |

| 12 | 1,75 | MHT 80/112 | 19 | 7,7 | 15,6 | 1,650 |

| 14 | 2.00 | MHT 80/114 | 22 | 8,5 | 17,2 | 2,480 |

| 16 | 2 | MHT 80/116 | 24 | 9,5 | 19,2 | 3,225 |

| 18 | 2.50 | MHT 80/118 | 27 | 10,4 | 21 | 4,410 |

| 20 | 2.50 | MHT 80/120 | 30 | 11,5 | 22,4 | 6,025 |

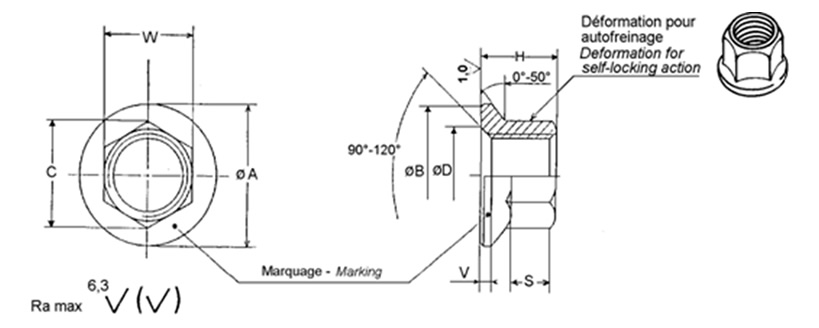

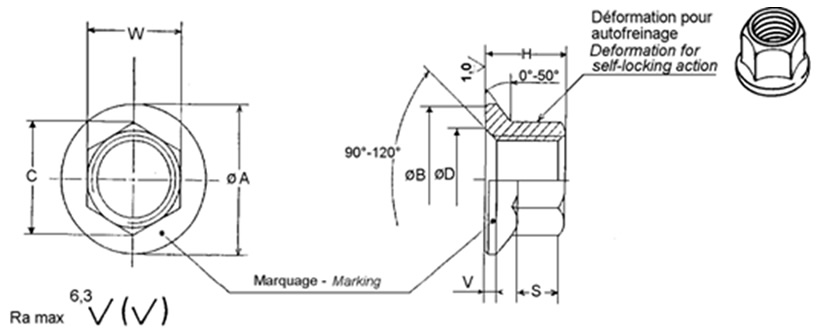

3. PH 105top

- The top!

- 425 °C

- unbelievable control of locking torque

- consistency of torques

| DESIGNATION SIMMONDS SIMMONDS PART NUMBER |

FILETAGE THREAD |

A max. |

B min. |

C min. |

D max. |

D min. |

H max. |

S min. |

V min. |

W min. |

W min. |

MASSE WEIGHT Kg 100pcs APPROX |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3050 PH 105 | MJ3 x 0,5 - 4H6H | 6 | 5,3 | 4,2 | 3,8 | 3,2 | 3 | 1,2 | 0,4 | 4 | h12 | 0,028 |

| 4070 PH 105 | MJ4 x 0,7 - 4H6H | 7,4 | 6,7 | 5,3 | 4,8 | 4,2 | 4 | 1,5 | 0,5 | 5 | h12 | 0,050 |

| 5080 PH 105 | MJ5 x 0,8 - 4H6H | 9,1 | 8,3 | 6,5 | 5,8 | 5,2 | 5 | 2 | 0,6 | 6 | h12 | 0,080 |

| 6100 PH 105 | MJ6 x 1,0 - 4H5H | 10,6 | 9,8 | 7,6 | 7,1 | 6,3 | 5,4 | 2,3 | 0,7 | 7 | h12 | 0,115 |

| 7100 PH 105 | MJ7 x 1,0 - 4H5H | 12,1 | 11,3 | 8,7 | 8,1 | 7,3 | 6,3 | 2,7 | 0,8 | 8 | h12 | 0,170 |

| 8100 PH 105 | MJ8 x 1,0 - 4H5H | 13,6 | 12,8 | 10,9 | 9,1 | 8,3 | 7,2 | 3,2 | 0,9 | 10 | h13 | 0,315 |

| 10125 PH 105 | MJ10 x 1,25 - 4H5H | 16,8 | 15,8 | 13,2 | 11,1 | 10,3 | 9 | 3,8 | 1,1 | 12 | h13 | 0,475 |

| 12125 PH 105 | MJ12 x 1,25 - 4H5H | 19,9 | 18,8 | 15,5 | 13,1 | 12,3 | 10,8 | 4,5 | 1,4 | 14 | h13 | 1,00 |

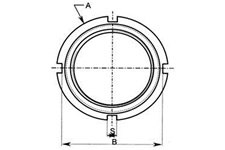

4. CN CF

Please consult us for the exact dimensions of the CN70 series. Dependant on availability we will offer you both alternatives.

| D | PITCH | H max. |

h min. |

A h11 |

E = B = C -0,5 | S H13 |

N° of slots | REFERENCE | OLD REFERENCE WITH DIFFERENT DIMENSIONS | |

|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 1 | 13,2 | 9,6 | 32 | 27 | 4 | 4 | VSNHC 20 | CF70-20 | |

| 25 | 1,5 | 14,2 | 10,0 | 38 | 33 | 5 | 4 | VSNHC 25 | CF70-25 | |

| 30 | 1,5 | 14,2 | 10,0 | 44 | 38 | 5 | 4 | VSNHC 30 | CF70-30 | |

| 35 | 1,5 | 15,2 | 10,6 | 50 | 44 | 5 | 4 | VSNHC 35 | CF70-35 | |

| 40 | 1,5 | 16,7 | 11,9 | 56 | 50 | 6 | 4 | VSNHC 40 | CF70-40 | |

| 45 | 1,5 | 16,7 | 11,9 | 62 | 55 | 6 | 4 | VSNHC 45 | CF70-45 | |

| 50 | 1,5 | 18,7 | 13,9 | 68 | 61 | 6 | 4 | VSNHC 50 | CF70-50 | |

| 55 | 2 | 18,7 | 12,9 | 75 | 68 | 7 | 6 | VSNHC 55 | CF70-55 | |

| 60 | 2 | 18,7 | 12,9 | 80 | 73 | 7 | 6 | VSNHC 60 | CF70-60 | |

| 65 | 2 | 19,7 | 13,9 | 85 | 77 | 7 | 6 | VSNHC 65 | CF70-65 | |

| 70 | 2 | 19,7 | 13,9 | 92 | 84 | 8 | 6 | VSNHC 70 | CF70-70 | |

| 75 | 2 | 20,7 | 14,9 | 98 | 89 | 8 | 6 | VSNHC 75 | CF70-75 | |

| 80 | 2 | 20,7 | 14,9 | 105 | 96 | 10 | 8 | VSNHC 80 | CF70-80 | |

| 85 | 2 | 21,7 | 15,9 | 110 | 100 | 10 | 8 | VSNHC 85 | CF70-85 | |

| 90 | 2 | 21,7 | 15,9 | 120 | 110 | 10 | 8 | VSNHC 90 | CF70-90 | |

| 95 | 2 | 22,2 | 17,1 | 125 | 115 | 10 | 8 | VSNHC 95 | CF70-98 | |

| 100 | 2 | 24,2 | 18,4 | 130 | 120 | 10 | 8 | VSNHC 100 | CF70-100 |

5. PH 135

| DESIGNATION SIMMONDS SIMMONDS PART NUMBER |

FILETAGE THREAD |

A max. |

B min. |

C min. |

D max. |

D min. |

H max. |

S min. |

V min. |

W min. |

W min. |

MASSE WEIGHT Kg 100pcs APPROX |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3050 PH 135 | MJ3 x 0,5 - 4H6H | 6 | 5,3 | 4,2 | 3,8 | 3,2 | 3 | 1,2 | 0,4 | 4 | h12 | 0,028 |

| 4070 PH 135 | MJ4 x 0,7 - 4H6H | 7,4 | 6,7 | 5,3 | 4,8 | 4,2 | 4 | 1,5 | 0,5 | 5 | h12 | 0,050 |

| 5080 PH 135 | MJ5 x 0,8 - 4H6H | 9,1 | 8,3 | 6,5 | 5,8 | 5,2 | 5 | 2 | 0,6 | 6 | h12 | 0,080 |

| 6100 PH 135 | MJ6 x 1,0 - 4H5H | 10,6 | 9,8 | 7,6 | 7,1 | 6,3 | 5,4 | 2,3 | 0,7 | 7 | h12 | 0,115 |

| 7100 PH 135 | MJ7 x 1,0 - 4H5H | 12,1 | 11,3 | 8,7 | 8,1 | 7,3 | 6,3 | 2,7 | 0,8 | 8 | h12 | 0,170 |

| 8100 PH 135 | MJ8 x 1,0 - 4H5H | 13,6 | 12,8 | 10,9 | 9,1 | 8,3 | 7,2 | 3,2 | 0,9 | 10 | h13 | 0,315 |

| 10125 PH 105 | MJ10 x 1,25 - 4H5H | 16,8 | 15,8 | 13,2 | 11,1 | 10,3 | 9 | 3,8 | 1,1 | 12 | h13 | 0,475 |

| 12125 PH 135 | MJ12 x 1,25 - 4H5H | 19,9 | 18,8 | 15,5 | 13,1 | 12,3 | 10,8 | 4,5 | 1,4 | 14 | h13 | 1,00 |

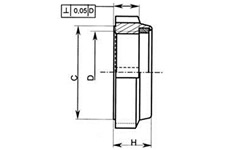

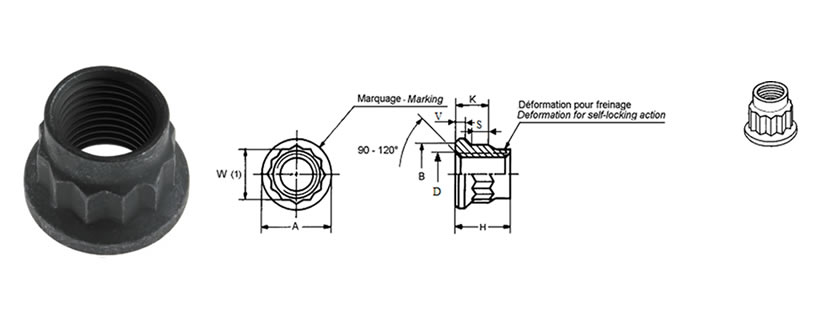

6. 12 point nut DHE series

| DESIGNATION SIMMONDS SIMMONDS PART NUMBER |

FILETAGE THREAD |

A max. |

B min. |

D max. |

D min. |

H max. |

K max. |

S min. |

V min. |

W (1) |

MASSE WEIGHT Kg 100pcs |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 4070 DHE 235 M | MJ4x0,70 - 4H6H | 7,4 | 6,7 | 4,8 | 4,2 | 5,6 | 4,2 | 1,8 | 1,2 | 6 | 0,14 |

| 5080 DHE 235 M | MJ5x0,80 - 4H6H | 9,1 | 8,3 | 5,8 | 5,2 | 7 | 4,9 | 2 | 1,2 | 7 | 0,18 |

| 6100 DHE 235 M | MJ6x1,00 - 4H5H | 10,6 | 9,8 | 7,1 | 6,3 | 8,1 | 5,5 | 2,3 | 1,2 | 8 | 0,22 |

| 7100 DHE 235 M | MJ7x1,00 - 4H5H | 12,1 | 11,3 | 8,1 | 7,3 | 9,1 | 6,1 | 2,6 | 1,2 | 9 | 0,30 |

| 8100 DHE 235 M | MJ8x1,00 - 4H5H | 13,6 | 12,8 | 9,1 | 8,3 | 11,1 | 6,7 | 2,8 | 1,2 | 10 | 0,45 |

| 10125 DHE 235 M | MJ10x1,25 - 4H5H | 16,8 | 15,8 | 11,1 | 10,3 | 13 | 8,8 | 3,1 | 1,2 | 12 | 0,78 |

| 12125 DHE 235 M | MJ12x1,25 - 4H5H | 19,9 | 18,8 | 13,1 | 12 | 15 | 9,5 | 3,5 | 1,4 | 14 | 1,20 |

| 14150 DHE 235 M | MJ14x1,50 – 4H5H | 23 | 21,9 | 15,2 | 14 | 17,5 | 11,2 | 4 | 1,7 | 17 | 2,35 |

| 16150 DHE 235 M | MJ16x1,50 – 4H5H | 26 | 24,9 | 17,2 | 16,4 | 20 | 12,3 | 4,7 | 1,9 | 19 | 2,90 |

| 18150 DHE 235 M | MJ18x1,50 – 4H5H | 29,1 | 28 | 19,2 | 18 | 22,5 | 14,2 | 5,6 | 2,1 | 22 | 4,00 |

| 20150 DHE 235 M | MJ20x1,50 – 4H5H | 32,3 | 31,2 | 21,2 | 20 | 25 | 16,2 | 6,8 | 2,3 | 24 | 5,30 |

| 22150 DHE 235 M | MJ22x1,50 – 4H5H | 35,4 | 34,3 | 23,2 | 22,4 | 27,5 | 17,6 | 8,3 | 2,5 | 27 | 6,00 |

| 24200 DHE 235 M | MJ24x2,00 – 4H5H | 39 | 36,9 | 25,3 | 24 | 30 | 19,4 | 10,1 | 2,7 | 30 | 8,00 |

12 point nut - allowing very high torque control. Ideal for difficult reach applications

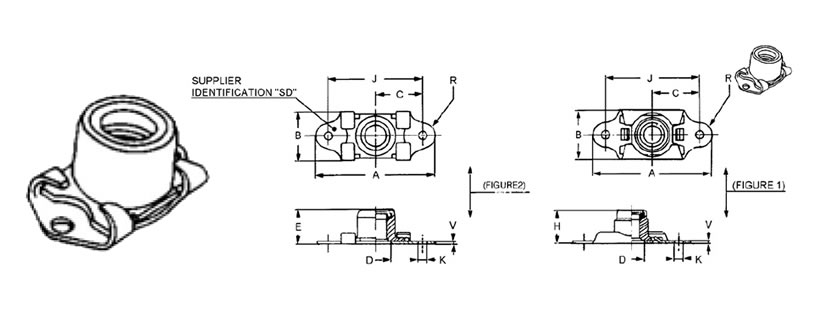

NLA 069-6, SNLA 069 Nut

SNLA 069-6, SNLA 069 Nut - Anchor, Two Lug, Floating, Narrow - 250° F

| Available part numbers | Alternate part numbers |

|---|---|

| SNLA 069-04 | MS21077-04 |

| SNLA 069-06 | MS21077-06 |

| SNLA 069-08 | MS21077-08 |

| SNLA 069-3 | MS21077-3 |

| SNLA 069-4 | MS21077-4 |

| SNLA 069-5 | MS21077-5 |

| SNLA 069-6 | MS21077-6 |

| SNLA 069-7 | MS21077-7 |

| SNLA 069-7Q | MS21077-7Q |

| SNLA 069-8 | MS21077-8 |

| SNLA 069-8Q | MS21077-8Q |

Contact Anemo Engineering for detailed drawings on the required SNLA 069 part number

- MATERIAL: Alloy steel heat treated.

- FINISH: Cadmium plate AMS-QQ-P-416, type II, class 2.

- LOCKING INSERT: Gold color nylon (250° F max. performance).

- PERFORMANCE: NASM 25027 applicable.

- THREADS: In accordance with AS-8879

- FLOATABILITY: Float of the nut portion of assembly shall not be less than .030 laterally and longitudinally from centre position. maximum vertical float .020 for .1900 size and smaller .030 for .2500 size and larger.

- APPLICATION: Type SNLA parts are designed for use with oversize clearance holes to permit interchangeable mounting of parts and sub-assemblies with a lesser degree of alignment accuracy than is usually required with fixed nuts.

- VARIATION: Add « K » for bottom c’sunk rivet holes, for example: SNLA-069-3K.

NOTES: For oversize rivet holes, (.161 DIA. for sizes -7 and -8 per NASM 21077) add code Q after the reference (ex: SNLA 069-7Q) .This variation is subject to a minimum order quantity if not available from stock. The P/N SNLA 069-7 and SNLA 069-8 do not conform to NASM 21077.

Benefits

- Lightweight - Thin walled nuts, takes less space

- Very high resistance to loosening

- Very high mechanical resistance 1100 MPA

- Very high locking torque

- Consistency of performance - Almost no locking torque scatter

- Flanged - Ideal for thin sheet material

- Temperature & Corrosion resistance - Operating temperature range between -40°C and 480°C, manufactured in CRES A286 Stainless Steel silver plated

- Re-usability - Can be fastened and unfastened a minimum of 15 times without compromising minimum required performance

We can supply also following Aerospace nuts:

DHE7-10CM , DHE7-11CM , DHE7-12CM, DHE10TD, DHE10TJ, DHE11TD, DHE11TJ, DHE12TD, DHE12TJ, DHE235M, JSMR10209M , JSMR30209M, JSR10009M, JSRT20009M, PH-105, PH135M, PHR135M, SR1009M, JSMR20209M, JSMR40209M, PH10TJ, PH105, PH115, PH135M, PH145, PH135M, PH145, PHR105, PHR115, PHR135M, PHR145, PHR105, PHR115, PHR135M, PHR145, SR1005

Contact us to receive the specific technical drawing

Following special parts we have also drawings off and can be manufactured for you, please take into account that minimum quantities will apply

Other special simmonds parts:

CR6485, CR6514, CR6514-1, CR6521, CR6591, CR6591-1, CR6614, CR6650, CR6673, CR6678, CR6696, CR6716, CR6761, CR6767, CR6833, CR6986, CR8000, CR8001, CR8002, CR8032, CR8042, CR8051, CR8067, CR8068

Simmonds other parts:

CR4291, CR5646, CR6458, CR6550, CR6656, CR6657, CR6831, CR6876, CR6888, CR6894, CR6897, CR6950, CRCR6975, CR6987, CR8073, CR8088

Simmonds Welding nuts :

CR6439, CR6552, CR6553, CR6652, CR6832, CR8073, CR8043, CR8043, CR8062, CR8063

Simmonds locking nuts complete out of metal:

CR5853, CR5865, CR6086, CR6111, CR6199, CR6359, CR6675, CR6951

Simmonds locking nuts complete out of metal with integrated washer function:

CR6064, CR6120, CR6269, CR6674, CR6952

Simmonds nuts (not locking)

CR5113, CR5146, CR5935, CR6362, CR6635, CR6649, CR6668, CR6690, CR6697, CR6711, CR6759, CR6760, CR6781, CR6786, CR6885, CR6903, CR6904, CR6973, CR6979, CR8027, CR8039, CR8041, CR8061

Simmonds nuts with washer- loose – (not locking)

CR6286, CR6712, CR6777, CR6812, CR6813, CR6814, CR6824, CR6976, CR6980, CR8030

Simmonds nuts symmetric simple style – (not locking)

CR6608, CR6834, CR6858, CR6878, CR6898, CR8029

Simmonds drivers (pignon & entraineur)

CR6515, CR6630, CR6619, CR6633, CR6823, CR6612, CR6806

Simmonds pins (manchon)

CR6654, CR6726

Simmonds special nystop nuts:

skirt nut, nylstop embase tournante elastique, écrou à jupe, ecrou nylstop a embase, nylstop a cone, écrou nylstop a rondelle tournante, CR6972, CR8055, CR5359, CR5713, CR5910, CR6025, CR6080, CR6087, CR6095, CR6144, CR6156, CR6270, CR6461, CR6476, CR6544, CR6607, CR6685, CR6899, CR8071, CR5801, CR5943, CR5955, CR6351, CR6450, CR6524, CR6559, CR6648, CR6702, CR6709, CR6713, CR6722, CR6763, CR8036

Simmonds is a registered brand name from ![]()