What's the difference between a Clinsert Installation tool and the other part number I requested?

- English

- Français

- Nederlands

- Español

- Deutsch

- Português

Clinsert tools are tools that will do the same job as the other tool part number you requested.

both tools are made to install the same insert.

since not all tools, even the original ones are made to a standard drawing, they can deviate from one delivery to another.

before delivery you can always request a picture of the tool that we have in stock.

example:

comparison between

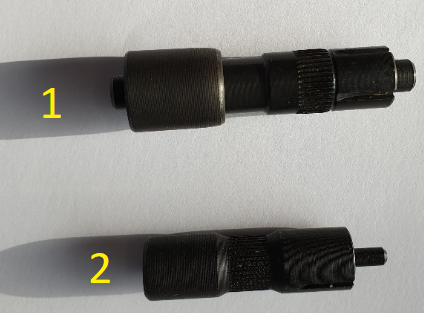

THD1032L = original part number tool that was requested: see picture next to number 1

CLHT1032 = alternative clinsert installation tool, number 2

the physical difference between both tools you immediately see is that tool THD1032L comes with a sleeve and the clinsert tool, does not have a sleeve:

The sleeve prevents the kees to bent during installation.

the way tool 1 works is by first turning in the keensert by help of the slots on the left side of the installation tool. Then twist the tool and hammer on the left side the kees in, while holding the sleeve in the position 1A.

one could ask if the sleeve function is something that is effective enough. therefore the clinsert tools have pre-notched holes, that keep the kees or clins straight, it's another way and more economical. You do not have to twist the tool, but can just turn in the kees with the slots and then lift it a bit up and put the kees inside the notches, and then hammer on the tool. Advantage with this option, is that you see while installing if your kees are bent or not.

The notched hole tool = clinsert tooling installs inserts in difficult to reach places, such as countersunk holes.