Bumpy Bumpers

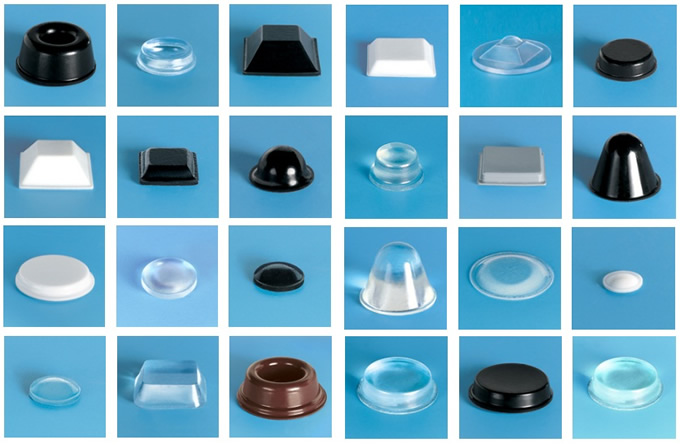

Most common bumpers

The technical drawing will be send to you by e-mail.

Bumpers are required to be purchase per minimum quantity required,

here you can see the box quantity

| Series | Quantity | quantity/sheet | weight | size of box |

|---|---|---|---|---|

| 2 series | 5082 pieces | 200 pieces / sheet | 3 kg | 86x34x17cm |

| 7 series | 5400 pieces | 450 pieces / sheet | 1 kg | 34cmx14x11cm |

| 12 series | 7200 pieces | 288 pieces / sheet | 3 kg | 86x34x17cm |

| 27 series | 5400 pieces | 450 pieces / sheet | 1 kg | 34cmx14x11cm |

| 40 series | 15028 pieces | 578 pieces / sheet | 1 kg | 34cmx14x11cm |

ADHESIVE SYSTEMS

Application Instructions

To obtain a maximum bond, surfaces need to be smooth, non-porous, clean, dry and free of all debris, oils and solvents. Clean the surface with a low strength solvent such as isopropyl alcohol (rubbing alcohol) or heptane. Follow solvent manufacturer's precautionary warnings and suggested handling procedures when using solvents. Bend pad slightly grasping bumper on sides without touching the adhesive. Apply to surface with enough pressure to ensure a complete bond. Allow a dwell time of 24 hours before exposing to heavy force or weight. The composition of this product contains no migratory plasticizers of any kind, which would mar surfaces of contact.

Users should evaluate the suitability of our Bumpers for a specific application under actual conditions.

BSI-94 High Performance Acrylic Adhesive (Must be specified when ordering.)

ADHESIVE TYPE: Solvent Based, Low Temperature, High Shear, Quick Stick

SUBSTRATE: 2 mils polyester substrate on a 90 lb release liner, PE coated, bleached, super-bright white Kraft liner.

All available kind of standard bumpy bumpers

TYPICAL PROPERTIES

Static Shear Test 500+ hours* [PSTC**-07 Procedure A / ASTM*** B 3654]

Quick Tack-Stainless Steel 77 oz/in2 (338 g/cm2)

Peel Adhesion 64 oz/in (714 g/cm) [PSTC-3** / ASTM*** D 3330]

Substrate: Thickness

Basis Weight

Tensile Strength

2 mils (50 microns)

10,000 in2/lb (142,230 cm2/kg) typical value

28,000 psi MD (1,900,000 g/cm2)

Liner: Thickness

Basis Weight

6.2 mils (158 microns)

92.0 lb (151 g/m2)

Temperature: Application

End Use

65°F — 150°F (18°C — 65.6°C)

-40°F — 300°F (-40°C — 149°C)

Substrate Elongation 120% MD

Shelf Life 24 months based on accelerated aging

Storage 73.4°F (23°C) and 55% relative humidity

BSI-95 Aggressive Synthetic Rubber Adhesive (Standard Adhesive)

ADHESIVE TYPE: Solvent Based, High Shear

SUBSTRATE: 2 mils polyester substrate on a 90 lb release liner, PE coated, bleached, super-bright white Kraft liner.

Adhesive testing for the acrylic and synthetic rubber was conducted using a polyester carrier. This information sheet is for typical values and is not a specification. End user assumes the responsibility for suitable testing and approval of this product's functionality. Adhesives are resistant to water and detergents. Not recommended for use with aliphatic or aromatic hydrocarbons.

Notice to Purchaser

Information and specifications contained herein are believed to be reliable, but no assurance is given as to the accuracy or completeness of technical information or recommendations. The Sellers or Manufacturers sole undertaking with respect to the product in lieu of all warranties of any kind is to replace any of the product that is proved to be defective. Neither Seller nor Manufacturer makes any warranty or representation the product is suitable for any specific purpose, nor shall Seller or Manufacturer be liable for any incidental or consequential damages for breach of any expressed or implied warranty. No person is authorized to assume for Seller or Manufacturer any liability or obligation in regard to this product other than as expressly set forth in this paragraph.