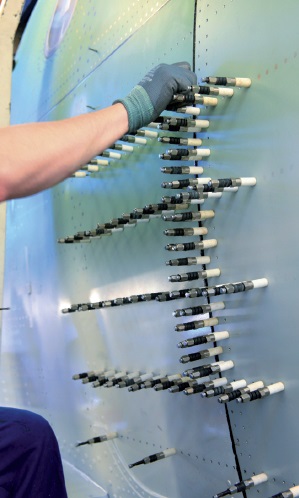

Temporary Fasteners

The temporary fastener or clecos are a solution proposed to customers solutions for their pre-assembly challenges. Our technical field experts have acquired a complete and thorough knowledge of aircraft pre-assembly and we manufacture today solutions for the following situations:

- Simple clamping

- Drilling template holding and metal or composite sheets clamping through the template

- Sealant/liquid shim squeeze out and drying

- Pre-load retaining

- Gap measurement

Plunger types or lead thread standard temporary fasteners allow the pre-assembly of all kind of material elements. Spring loaded or not, they are designed for efficient clamping in rubber sealant or resin applications.

Special high performance temporary fasteners and clecos answer to particular requirements such as :

- Large diameters

- Hard tool holding

- Wide structure thickness

- Clamping through hard tool bushings

A complete range of standard or special tools ensure adjustable pre-loads of the assembly as well as access in confined areas.

The range of CLAMPBERRY temporary fasteners or clecos are unique in the aerospace market. Built step by step to answer successive customer challenges, it represents today dozens of standards for various applications which can be declined in different diameters and grip ranges. Depending on the environment of the installation, on the structure to pre-assemble, on the tension to sustain, on the application to secure, we can provide the appropriate pre-assembly solution. The product range is wide but here are a few of our major technical concepts:

- for small thickness sheets pre-assembly under low pre-load, our manually operated Series 1000 and 1100

- for rubber sealant applications, our most common TF-26/-28/-41/-42/-44H series

- for drilling template holding and further structure clamping:

– our combination of TF-80 and TF-81 series for standard preassemblies,

– our TF-355, TF-351 and TF-352 series for confined areas and restricted environments - for more complex and precise pre-assemblies, our CAL concept

- for composite structures, our TF-CC, TF-CCG, TF-348CC, TF-350...

- for automated pre-assemblies, our newly TF-CCTFR, TF-61 and related effector

SUMMARY OF TEMPORARY FASTENERS

PLUNGER TYPE

|

Spring loaded plunger type fastener used to clamp low thickness parts. |

|

|

Spring loaded plunger type fastener used to clamp low thickness parts. |

LEAD THREAD TYPE

LEAD THREAD TYPE - Spring loaded (spring 60 daN)

|

Power operated temporary fastener. Low profile and low thickness for rubber sealant applications. |

LEAD THREAD TYPE - Spring loaded (spring 100 daN)

|

Power operated temporary fastener. Low profile and low thickness for rubber sealant applications. |

LEAD THREAD TYPE - Spring loaded (spring 200 daN)

|

Power operated temporary fastener. Low profile and low thickness for rubber sealant applications. |

LEAD THREAD TYPE - Spring loaded (spring 20 daN)

|

Power operated temporary fastener. Low profile and low thickness for rubber sealant applications. Teflon sleeve covered for resin applications. |

LEAD THREAD TYPE - Hex driving nut

LEAD THREAD TYPE - Cylindrical driving nut

THREAD TYPE - Miniature not spring loaded

|

Power operated temporary fastener. Very short and variable overall body lenght and special effectiveness and more confined area. |

LEAD THREAD TYPE - Not spring loaded

LEAD THREAD TYPE - Spring loaded. High Clamping performance

|

Power operated temporary fastener. Reduce volume design for being installed and removed in a confined area. Same compensation device than series 54. |

LEAD THREAD TYPE - Spring loaded. Hex driving nut

|

Power operated temporary fastener. Same advantages than series 30 but equipped with spring loaded for rubber sealant application. |

LEAD THREAD TYPE - Spring loaded. Cylindrical driving nut

LEAD THREAD TYPE - Spring loaded. Hex driving nut

|

Power operated temporary fastener called “marking” for positioning robot-end-effector. |

LEAD THREAD TYPE - Cylindrical driving nut

|

Power operated temporary fastener. Special for resin leveling applications in composite material that require low calibrated (± 5%) clamping load. |

LEAD THREAD TYPE - Hex driving nut

|

Same as series 44 but driver controls clamping load |

LEAD THREAD TYPE - Spring loaded. Cylindrical driving nut

|

Power operated temporary fastener. Special for hard tool positioning and clamping |

LEAD THREAD TYPE - Spring loaded. Hex driving nut

|

Power operated temporary fastener. Special for hard tool positioning and clamping |

LEAD THREAD TYPE - Spring loaded. High Clamping performance

|

Used for rubber sealant applications. H version has hex driving nut. |

LEAD THREAD TYPE - Spring loaded

|

Power operated temporary fastener. High clamping force. Special for hard tool positioning and clamping |

LEAD THREAD TYPE - No Spring loaded

|

Power operated temporary fastener. High clamping force |

LEAD THREAD TYPE - Spring loaded

LEAD THREAD TYPE - Spring loaded - C-sink cap

|

Power operated temporary fastener used for rubber sealant application. |

LEAD THREAD TYPE - Spring loaded

LEAD THREAD TYPE - Spring loaded - Cylindrical driving nut and body

|

Hybrid temporary fastener, cylindrical design and hex lock. Same advantages as series 42 with incorporated spring. Installation and removal is performed by a roller bearing drive system. |

LEAD THREAD TYPE

|

Operated by robot-end-effector |

LEAD THREAD TYPE - Spring loaded - Cylindrical driving nut

|

Power operated temporary fastener. Special for hard tool positioning and clamping |

LEAD THREAD TYPE - Spring loaded

|

Power operated temporary fastener. High clamping force. For rubber sealant applications |

|

|

High clamping force. Calibrated for “concentric collet” system. Bearing area is optimized on 4 jaws. |

|

|

Double threaded rod for a quick installation and removal. For rubber sealant application. Grippers can be Teflon sleeve covered for resin applications. |

|

|

Double threaded rod for a quick installation and removal. For rubber sealant application. Grippers can be Teflon sleeve covered for resin applications. |