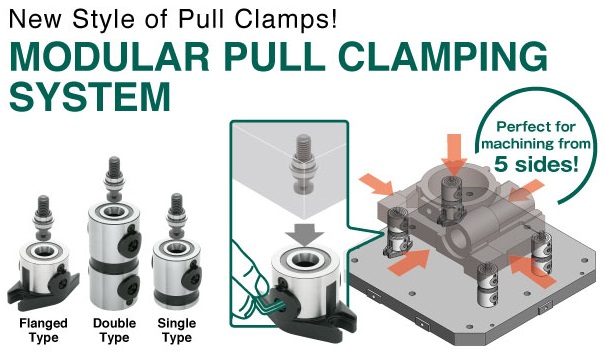

Modular pull clamping system

The cylindrical body allows machining from 5 sides without tool interference. Precise dual contact provides excellent locating repeatability at 5μm.

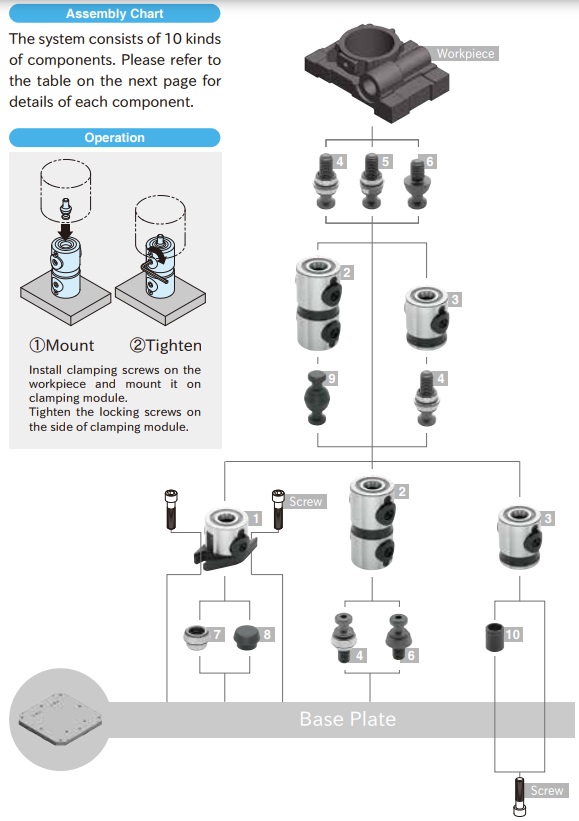

|

| CP150 |

|

| CP151 |

|

| CP152 |

|

| CP155 |

|

| CP156 |

|

| CP157 |

|

| CP158 |

|

| CP159 |

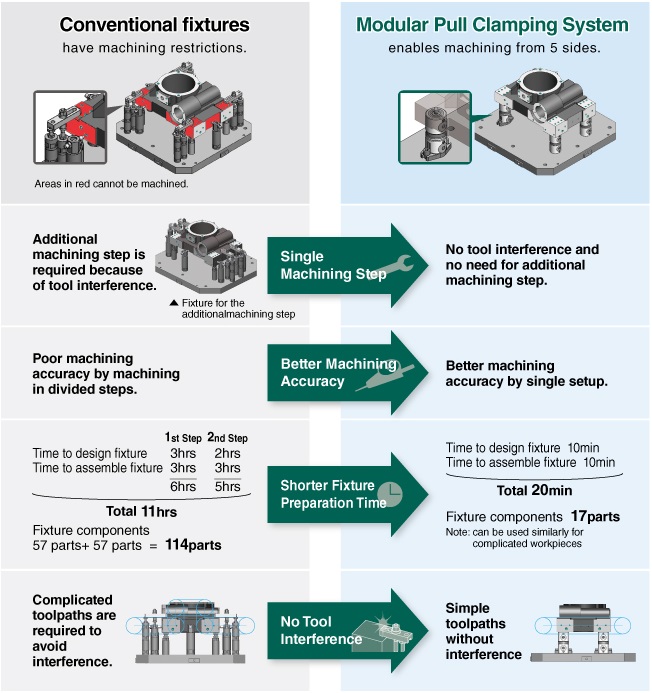

Comparaison to Conventional Fixtures

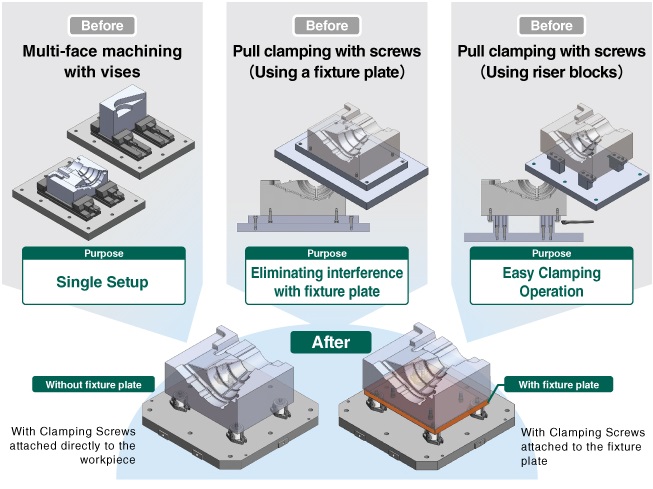

Application Examples

Improvement of Existing Fixtures

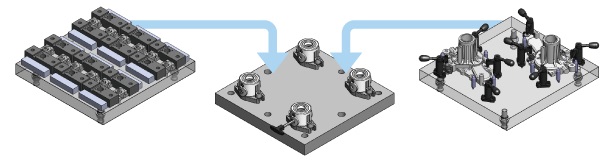

Precise Fixture Change

Modular Pull Clamping System allows quick and precise fixture change.

Modular Fixture

Can be used as a universal fixture by standardizing the mounting pitch for Clamping Screws

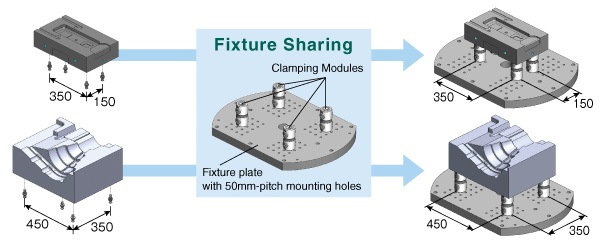

How To Use

Clamping Modules can be coupled with each types of Clamping Modules. For details, see the Assembly Chart in "How To Use Modular Pull Clamping System".

How To Use Modular Pull Clamping System

How To Use Clamping Screws

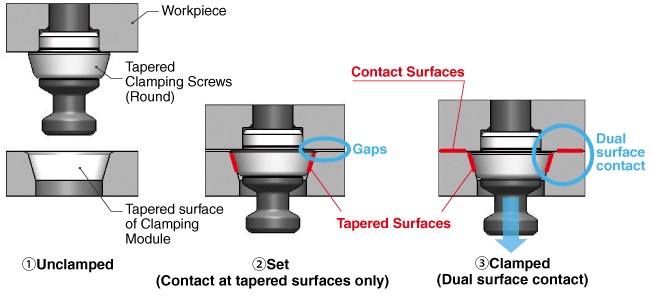

Tapered Clamping Screws - For precise locating

Clamping Screws - For clamping

Positioning Order of Tapered Clamping Screws

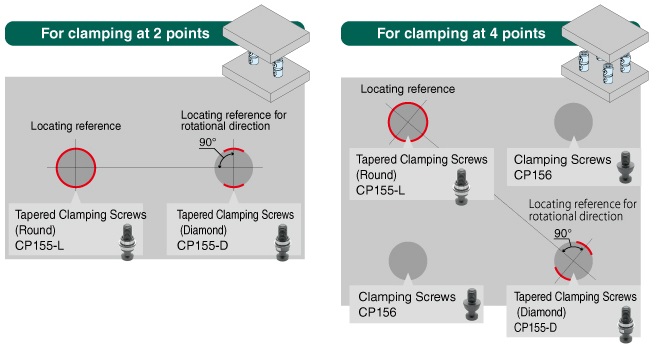

Mount the Round-Type and Diamond-Type as in the figure, for locating workpieces.

Note: Tighten the Round-Type first, and then Diamond-Type, and Clamping Screws last of all.

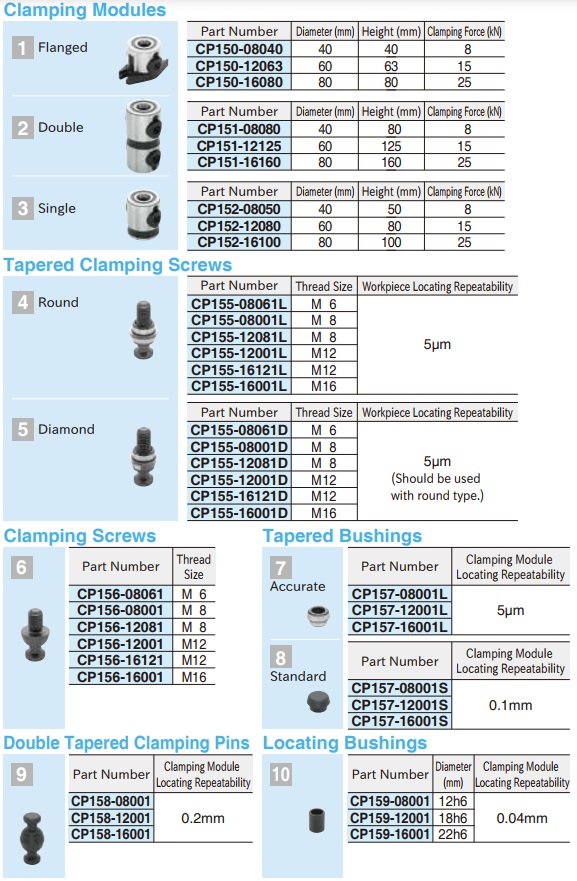

Locating Mechanism

Dual surface contact at the tapered surfaces and contact surfaces enables 5μm locating repeatability.