What is V2A and V4A stainless steel?

Both V2A and V4A stainless steels fall under the austenitic category, denoting their crystalline structure predominantly consists of austenite phase. The American SAE grade system identifies austenitic stainless steels by numbers beginning with 300. These steels typically comprise a maximum of 0.15% carbon, a minimum of 16% chromium, and adequate amounts of nickel and/or manganese to maintain an austenitic structure.

V4A stainless steel

V4A, a German standard, epitomizes resilience, making it ideal for hostile conditions. Its applications span diverse industries, including infrastructure, where it's employed in tunnels for fixing lights. Tunnels pose unique challenges such as high humidity and acidic atmospheres due to vehicle emissions, where V4A's corrosion resistance shines. Belonging to the 316L family, V4A variants like 1.4404 or 1.4435 offer superior protection against corrosion, thanks to their low carbon content (indicated by "L" designation).

| EN standard | steel name | SAE grade |

| 4307 | X2CrNi18-9 | 304L |

| 1.4306 | X2CrNi19-11 | 304L |

| 1.4311 | X2CrNiN18-10 | 304LN |

| 1.4301 | X5CrNi18-10 | 304 |

| 1.4948 | X6CrNi18-11 | 304H |

| 1.4404 | X2CrNiMo17-12-2 | 316L |

| 1.4401 | X5CrNiMo17-12-2 | 316 |

| 1.4406 | X2CrNiMoN17-12-2 | 316LN |

| 1.4432 | X2CrNiMo17-12-3 | 316L |

| 1.4435 | X2CrNiMo18-14-3 | 316L |

| 1.4436 | X3CrNiMo17-13-3 | 316 |

| 1.4571 | X6CrNiMoTi17-12-2 | 316Ti |

| 1.4429 | X2CrNiMoN17-13-3 | 316LN |

Referencing the EN standard, various steel names correspond to SAE grades. For instance:

- 1.4404 (X2CrNiMo17-12-2) and 1.4435 (X2CrNiMo18-14-3) signify 316L grade, known for its corrosion resistance in aggressive environments.

- The "L" designation denotes carbon content below 0.03%, crucial for mitigating corrosion risks post-welding.

Despite their divergent compositions, both V2A and V4A exhibit comparable performance, especially in resisting salt spray corrosion. However, nuanced differences exist in their base material compositions, evident in the variations outlined in the steel names.

V2A stainless steel

V2A, akin to 1.4301 or AISI 304, embodies versatility and reliability. While not as impervious as V4A, it finds applications across industries where moderate corrosion resistance suffices. Its composition, akin to 304 grade, ensures durability and longevity, making it a cost-effective solution for numerous applications.

V1A vs 1.4305 or AISI3

V1A is similar to 1.4305 or aisi 303 (see separate blog)

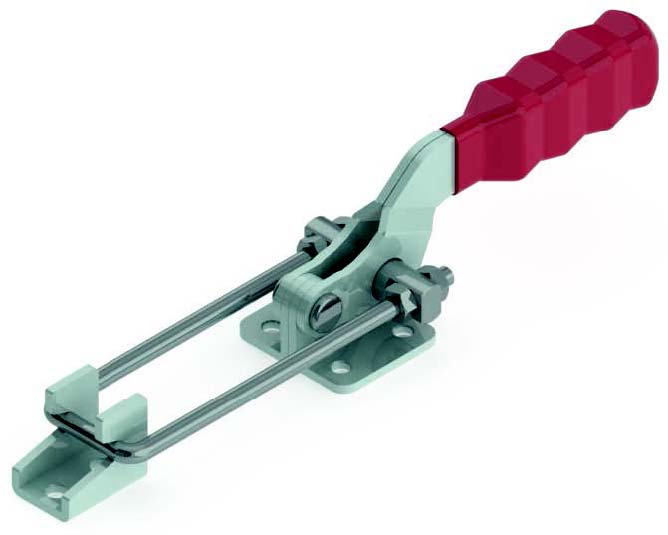

We developed a full line of stainless steel 316 = V4A latches and clamps!

View our full range of stainless steel clamps nuts and latches hinges and handles on https://www.stainless-steel-316.com/

https://www.stainless-steel-316.com/stainless-steel-316/stainless-steel-a316-bolts-and-screws/

You can also review our Stainless steel clamps here: https://anemo.eu/s-clamps/stainless-steel-316

We also have standard clamps available in stainless steel 316:

- small latch PAH-27-1900-SS-316

- clamp PAH-331-TRIG-SS-316

- horizontal hold down action clamp: H-1323-UB-SS-316

- vertical hold down action clamp: VTC-1625-UB-SS-316

- and many more clamps that are available in full stainless steel 316

Download Stainless Steel 316 catalogue

Another product line we have available is stainless steel 316 (V4A stainless steel), are our Auto Lok Nuts

Some of which we have stock available are:

and others as well.

We help customers with the fast connection and disconnection of panels with quick-release fasteners and give technical advice about quarter turn, latches, lock pins,...