Technical questions about Nutrunner swing clamps

- English

- Français

- Nederlands

- Español

- Deutsch

- Português

Nutrunner swing Clamps serves as alternatives to hydraulic clamps is clamping automatisation.

Tightening with nut runner installed on a robot actuates Nutrunner clamps to hold workpieces with high clamping force in machining and assembly line.

Mechanical design does not require hydraulic piping and simplifies fixture design and maintenance.

Robotic clamps achieve automated workpiece clamping with shorter fixture preparation time and lower fixturing cost than hydraulic clamps.

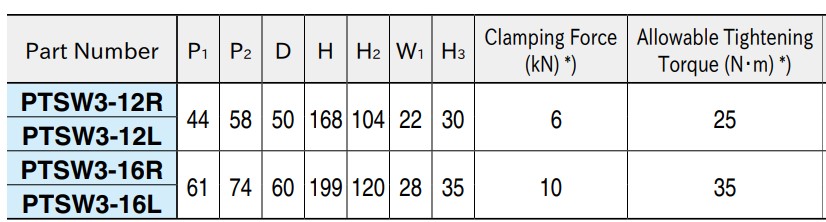

Parts number of Nutrunner swing clamps :

PTSW3-12R

PTSW3-12L

PTSW3-16R

PTSW3-16L

Technical Questions about nutrunner swing clamps :

1. Most important: when the nutrunner is open (so not in clamped position) that it stays in the 90° position, even when the clamp is hanging upside down, sideways or different

Yes, the clamping arm stays in the unclamping position even when it is hanging upside down.

2. once turned and when it goes downwoards towards the full clamping position, this range of when It goes downwoards, can it clamp on any position? And how much is that range? Imagine it’s not fully turned yet, and only at 60°, do you reach then also the rated clamping force?

No, you need to clamp the workpiece within the "clamping stroke" of the nutrunner clamp. While the arm is swinging (Clamp-Arm Travel), you cannot get enough clamping force.

3. What are the conditions that a nutrunner needs to comply too? In combination with the nutrunner clamps.

The nutrunner should generate enough tightening torque that is mentioned in the datasheet. Then you can get the clamping force shown there.

4. Parts are currently washed at 60° with water and cleaning agent for oil which is hakupur 700; future product will most likely be techniclean 80XBC ; cleaning is like a carwash, so parts are not dimpled under water but just sprayed. The worry, is they would start to rust. What’s your recommendation? I guess nutrunner parts are now lubrificated, will that lubrication disappear; and do parts contain O-rings?

Nutrunner clamps have o-rings to prevent metal chips and coolant from entering. So the inside of the clamp will not rust and lubrication will not disappear. But this does not continue forever. Some components may rust or lubrication may go out after long-time use. In such case, the customer needs to replace the component or purchase a new clamp.

5. The standard length they use is 90 and 120 ; occasionally 160 ; it’s not clear if imao produces the clamping arm or the customer, and what would be the required specifications.

Please see below the specs of the custom arm. The longer the arm becomes, the clamping force becomes lower.

Part No | A | B | C | D | E | F | G | H | J | K | L |

PTSW3-12 | 43 | 29 | 50 | 9 | 13 | 10,5 | 6,5 | 6,2 | 34,5 | 25 | 66 |

PTSW3-16 | 52 | 34 | 60 | 11 | 17 | 13,5 | 8,5 | 8,2 | 42 | 30 | 79 |